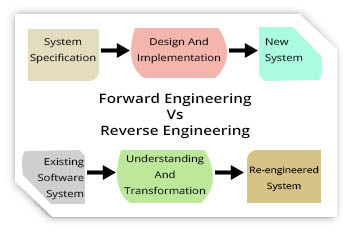

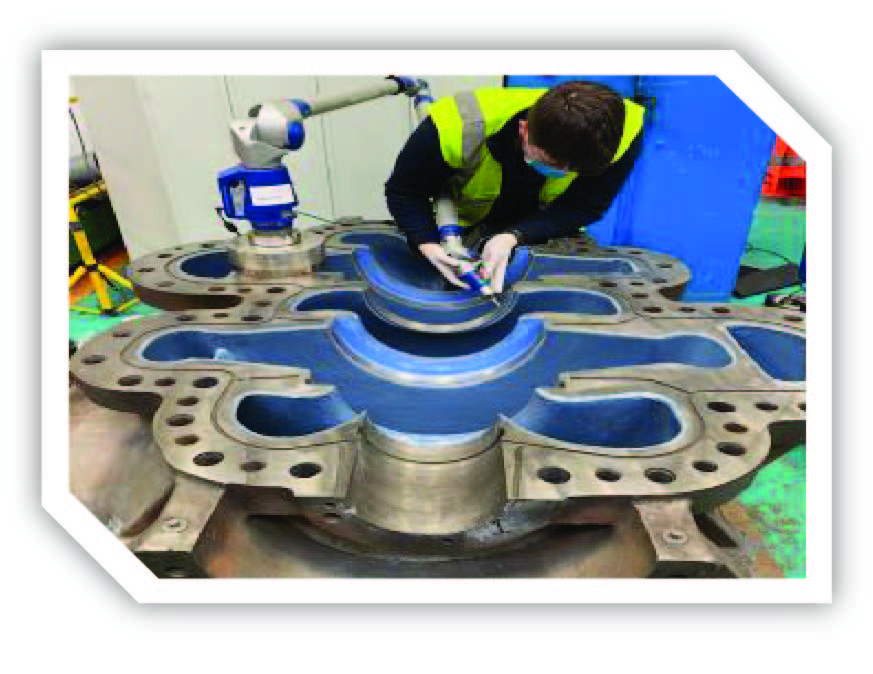

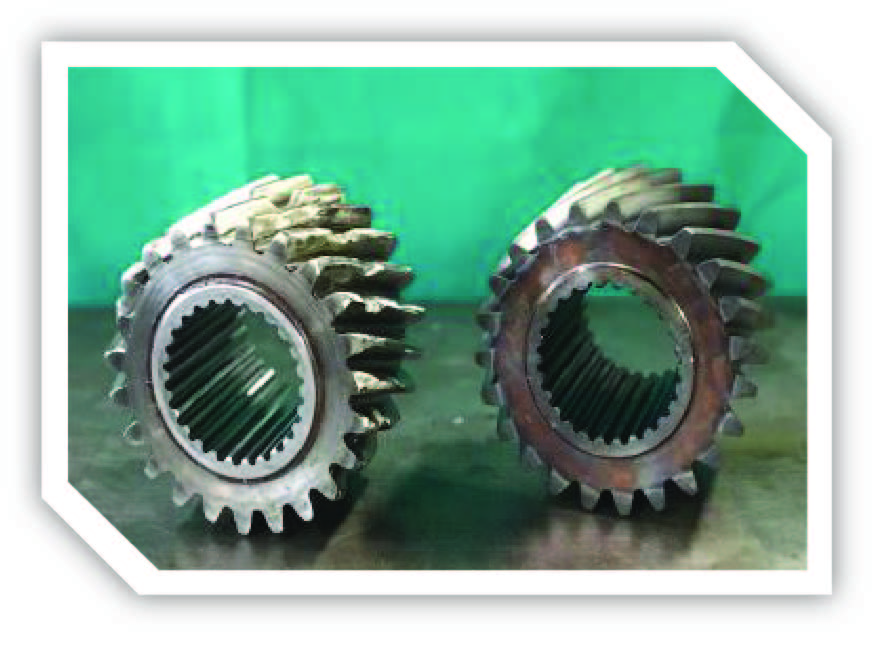

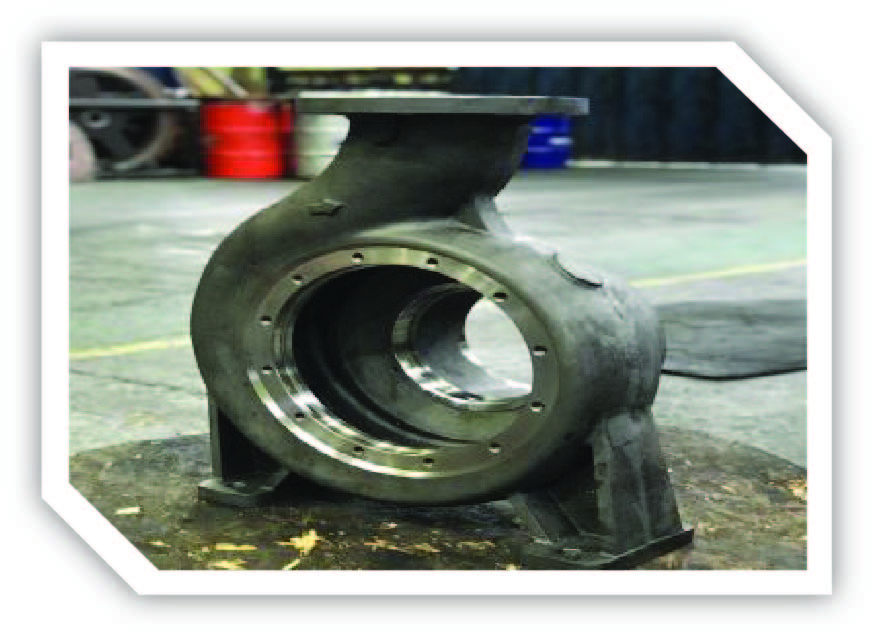

It’s a remanufacturing method that enable EPC to produce a part or complete system in case of obsolescence, deterioration, unavailability, or total damage using our highly accurate 3D Scanning technology. EPC can offer up to two years warranty on parts designed and manufactured under our responsibility. Below are some of the most common uses of reverse engineering offered by EPC in partnership with KARM design Ltd.

Some examples of our reverse engineering techniques and manufacturing capabilities

A qualitative methodology of tie-up process and practices through which an organization optimally and sustainably manages its capital physical and non-physical assets in a systematically effective way typically associated with their performance, risk, financial, operational, maintainability, and expenditures over their life cycles for the purpose of achieving its organizational strategic plan [Partially adapted from PAS 55-1:2008].

As a result of Asset Management benefits of optimized life cycle and in no particular order, EPC in association with our partner ARMs reliability have the capability offering the following

Key principles and attributes of asset management as integrated system consist of

The following enabling elements are also considered to be essential for the successful implementation of these principles

EPC have the capability, confidence, and competency to provide complete engineering package solutions for our clients to assure them that they get the services they deserve based on their desires from design stage, manufacturing to Operating & Maintenance manuals development.

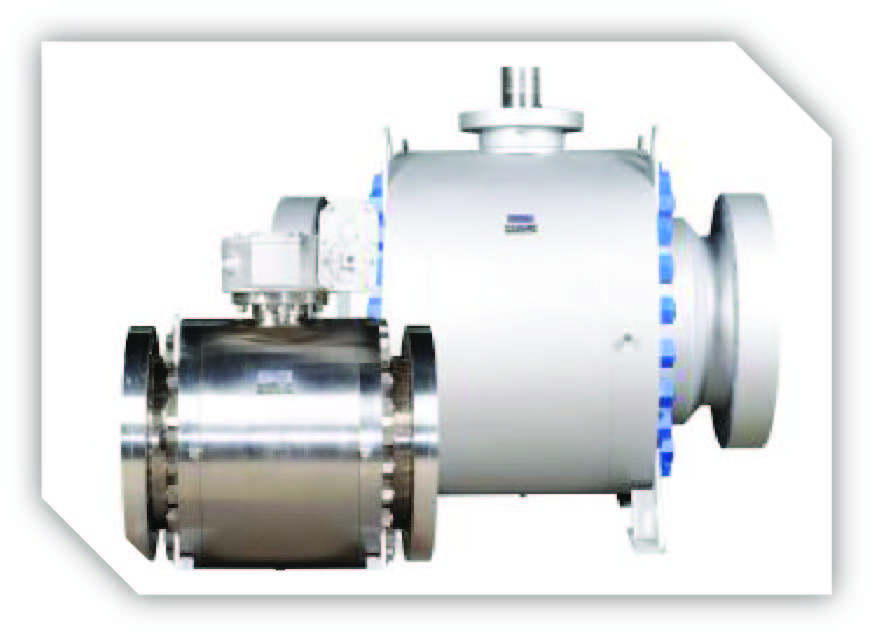

Our valve manufacturing partners have over 30 years of specialising in the Design and Manufacture of Ball Valves for the Oil, Gas, Chemical, Petrochemical, Pipeline and Water industries worldwide. Their valves are used in offshore, onshore and subsea applications

The organisation and flexibility of our company allows us to offer short lead-times, even on non-standard valves. All valves are manufactured to the highest quality standards and are fully tested before leaving the factory and with a stock list of over 500 valves of various sizes readily available for a reduced delivery time

EPC & KVC UK Ltd offer customers a vast range of services with aftermarket care ranging from parts and spares that are in stock or can offer quick manufacturing and turn around for spare parts or replacement seals for all types of valves.

KVC UK Ltd Focus on design & provision of valves to the highest quality standards

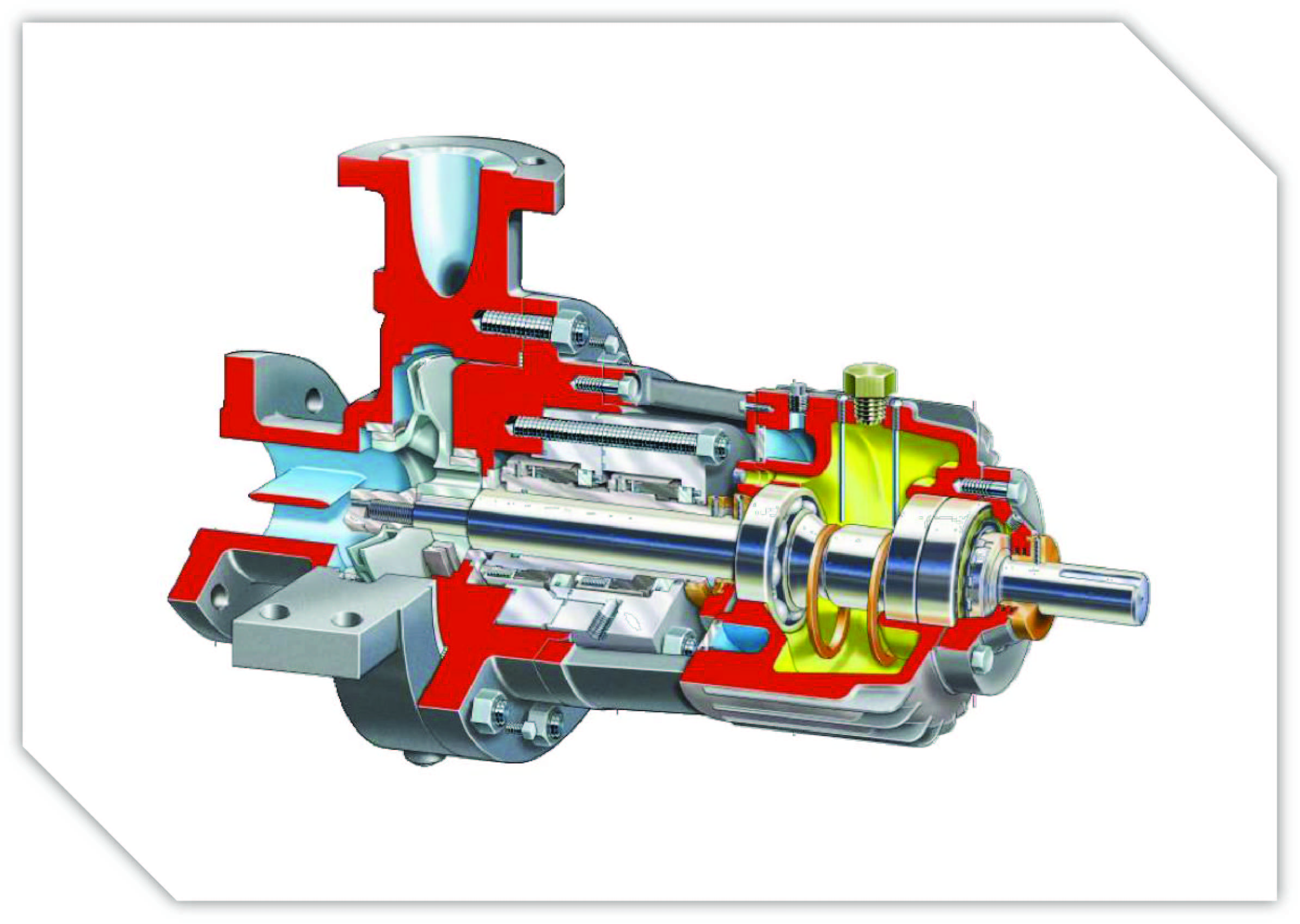

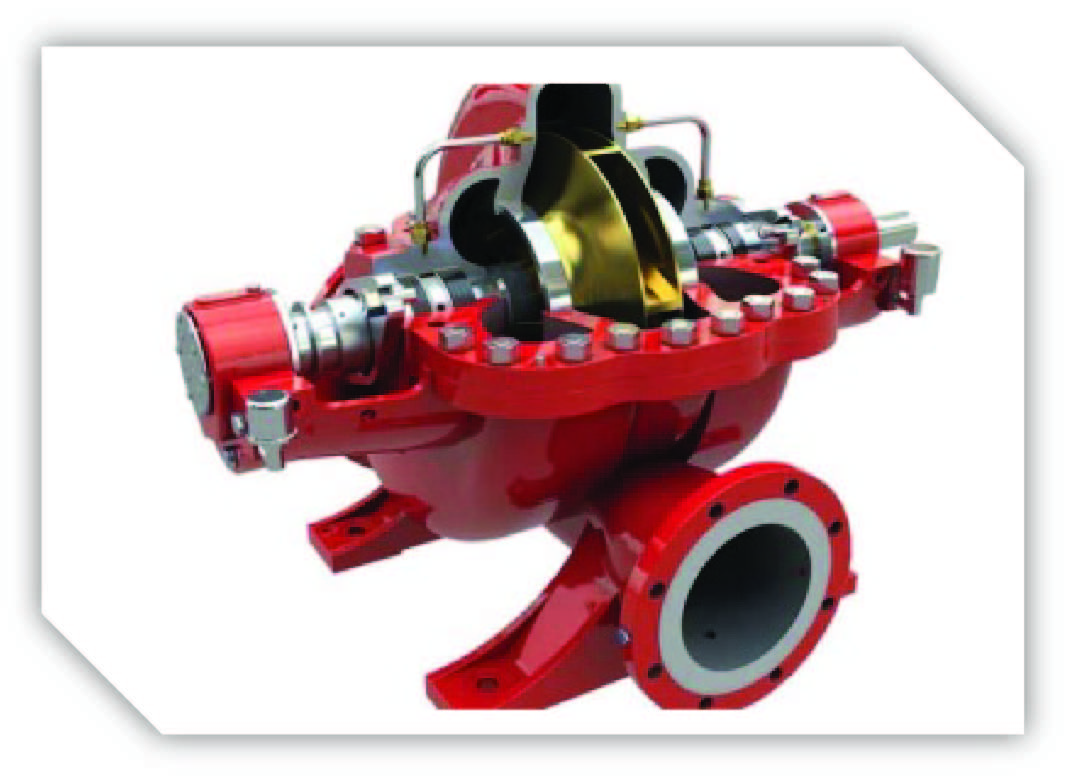

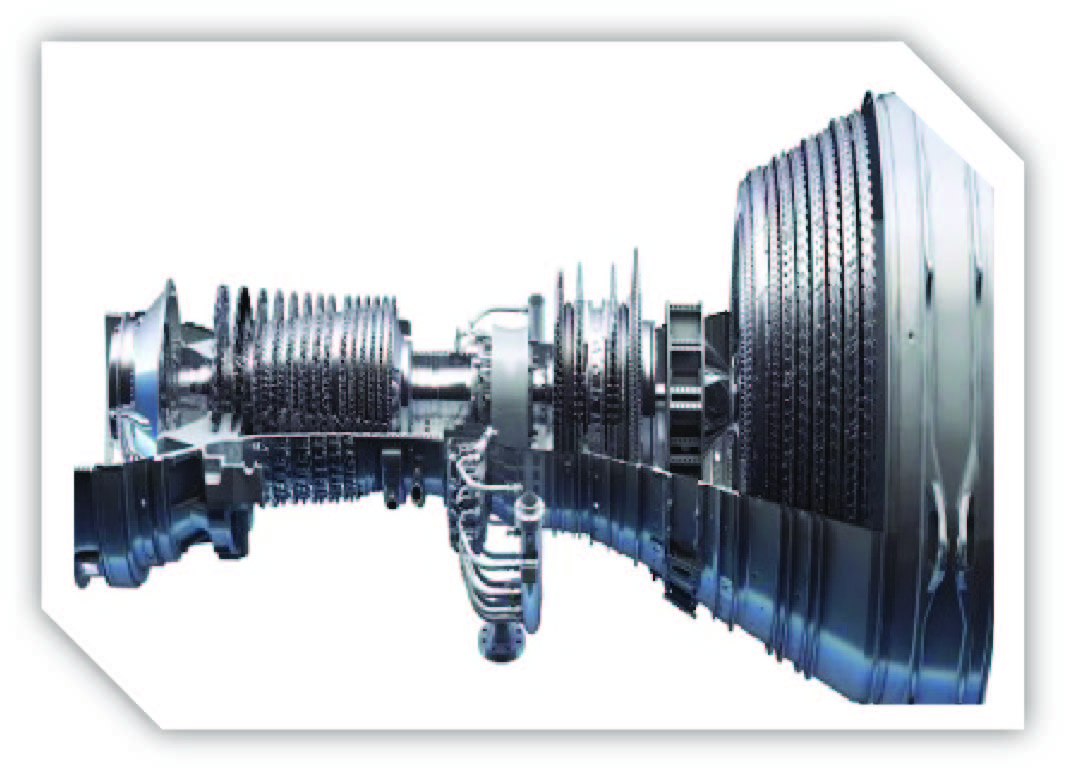

EPC’s aim is to provide comprehensive services on all rotating equipment offering a vast amount of engineering experience to support our client. Our team of engineer’s partners have over 40 years hands on experience in rotating equipment and all associated systems. covering all aspects from strip down, build up, overhauling, design & upgrades, onsite installation and commissioning along with carrying out RCA / troubleshooting on bad actors.

Brief list of technical training courses that can be presented:

EPC along with Atholl Industrial Solutions can offer vast field expertise which will help our customers resolve their power system instability issues / problems. We can provide our clients design-build solutions anchored by our power quality product lines. Furthermore, we will provide diagnostic testing and root cause analysis within each client’s unique power system that ensures a “one-stop” service plan to restore the operational integrity of the clients power system, which we will also provide electronics diagnostic testing and root cause analysis additional to that. The main benefit is for EPC to provide electronic cards repair, reprogram, build up new program software if needed based on our client’s requirement.

EPC aims to :

Resulting in

EPC uses ETAP advanced software by Operation Technologies to model AC and DC power systems. ETAP Star device protection and coordination program provides an intuitive and logical approach to time-overcurrent analysis. Star’s sequence-of-operation evaluates, verifies and confirms the operation and selectivity of the protective devices for various types of faults for any location right from the system one-line diagram.

ETAP Short Circuit and Load Flow modules allow the PSS analyst to calculate available fault currents and review loading profiles within the power system. Arc Flash Analysis is performed to ensure client compliance with NFPA 70E and IEEE 1584 national standards.

EPC along with ERG offers a comprehensive range of Odour and Air Pollution Control Systems and associated services.

The scope of supply ERG offers specifically covers the design, supply, installation and commissioning and maintenance of Odour and Air Pollution Control Systems

(i.e. ductwork, Odour or Air Pollution Control Unit, and associated ancillary equipment)

based on :

EPC & Ailsa specialise in solutions to improve customers reliability and availability of their plant and assets, using the latest condition monitoring equipment and technology available in the market.

With over 20 year’s experience in supporting customers, with various services, across a multitude of industry sectors, EPC understand how crucial uptime of process related equipment is to any organisation.

EPC can test, monitor, analyse, report and recommend solutions to critical items of mechanical and electrical plant to assure our customers of maximum uptime and availability reducing costly downtime and unplanned outages, thus increasing customer productivity and profitability

EPC and Britannia Lifting Ltd are a trusted name in inspection, testing, and certification services, Along the way we’ve gathered first-hand experience in all manner of assessment and testing techniques, across a broad range of worldwide industries.

Our pedigree gives our clients the reassurance of knowing you have a fully qualified and experienced engineers at your service; working to help reduce risk, shorten time to market and demonstrate the quality and safety of materials, components, or products.

Expertise

All kinds of business organisations count on our expertise, guidance, advice, and services.

Typically, these could include inspections, certification, the application of colour-coding

systems, safety training, load testing.

In most countries, Health & Safety legislation exists that applies to both premises and equipment. A prime example would be the UK’s Lifting Operations and Lifting Equipment Regulations (LOLER) which is now been implemented throughout the globe and with our international network, EPC and Britannia Lifting Ltd is perfectly placed to assist companies with the complexities of local and international regulations. Our teams of fully trained and qualified engineers can be relied upon to maintain optimum levels of safety and legality. We classify ourselves as a world-class leader in the provision of all aspects of industrial and health and safety training. From mobile crane operators, to lifting and slinging, plant operation through to general safety and environmental. We are the class leader.

certified courses have an enviable worldwide reputation of quality and excellence. Safe certified equipment is only as good as the operators, from this the skills and competency of our clients employees to international recognised standards is safe in the care of our hands. Training for any organisation is an ongoing investment in your people and refresher courses are essential to ensure they are up to date with current legislation and safe working practices.

Training programs are available on location using your own equipment for better familiarisation with the delegates